After a short introduction where we met different members of Logitech's management and developmental teams, we (the journalists) were split up into small groups and taken to different parts of the facility, so that we could get an insight into the different aspects of its runnings.

First stop, keyboards.

While Logitech might be more well known for its gaming mice, in recent years it's taken more of a focus on the left hand man of a hardcore gamer, the keyboard. Many gamers of course (and indeed, most professionals) use mechanical keyboards as they offer faster response times than your average membrane interface.

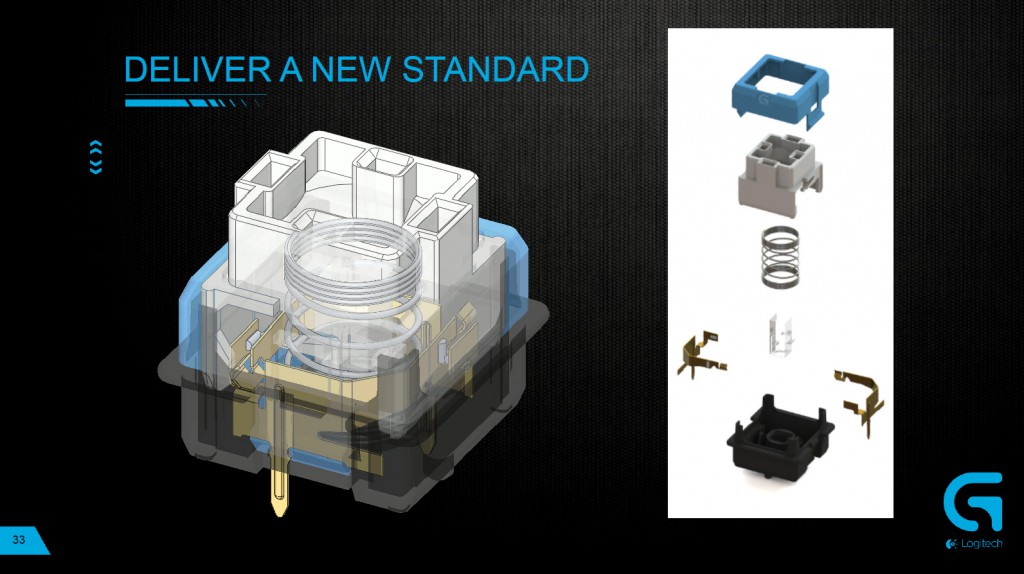

Most of them use Cherry MX switches, as they're the industry standard for mechanical keyboards. But that design is decades old at this point and Logitech felt it could go a step further and create its own switch that was faster, lasted longer and performed better over time. Enter, the Romer G.

If you've seen any press regarding the Logitech G910 Orion Spark (look out for our review soon) then you may know a little about this switch already, but in short, it's everything Logitech wanted it to be. It has a shorter travel distance, so actuates 30 per cent faster. It also has a sturdier construction and has been rated to maintain its 30 per cent speed improvement over 70 million clicks. Logitech didn't say how many it would take for it to fail, but to put it into context, Cherry MX switches are regularly rated to live for ‘just' 50 million presses.

These switches also have a double connector at their base, meaning there's redundancy should you happen to damage or spill something on the keyboard.

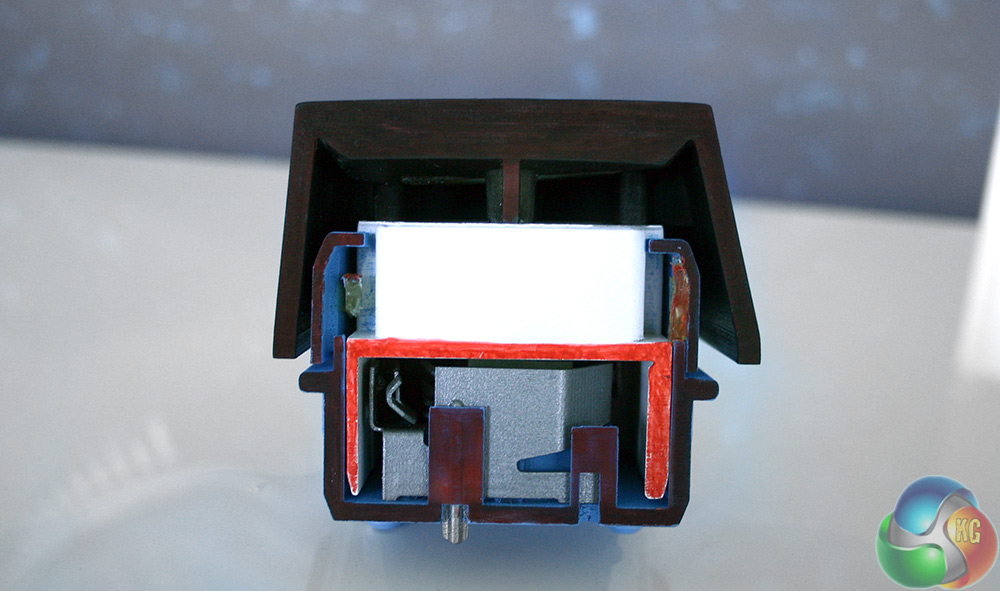

This is what a physical prototype of the Romer G switch looks like

Logitech didn't stop there however, it looked to professional gamers to ask what they wanted, prototyped various different slants to keys and even used heat mapping to pinpoint just where gamers like to rest their hands and where the pressure points are – IE, where more support is needed.

It is at this point that you might think it would be time to build the board, package it up and ship it out, but Logitech sees this as just the beginning. It prototyped several different versions of the G910 Orion Spark and even gave us one of its earlier ones to try. It had higher edged keycaps and was in short, horrible for typing, even though gaming worked quite well on it.

Back to the drawing board it was, but eventually after working with professional gamers and through its own internal testing, Logitech developed something that it was proud of. From there, it was time for the real testing to begin.

And so we were ushered into this room, featuring giant workstations and desks three deep (double sided) that had upwards of five testing stations a piece, each running some sort of testing profile on a particular piece of Logitech gear. Mostly its keyboards. [yframe url='http://www.youtube.com/watch?v=Tv8tS0Hlx4c']

Machines like this one hit the keys constantly for hours, days and weeks at a time to make sure that after thousands and millions of keystrokes, the Romer G switch continues to perform as it should. [yframe url='http://www.youtube.com/watch?v=lxI_6IHxp2o']

Mice get a look in too, as those Omron Switches need just as much testing. Similarly this machine also pushed it to see how many clicks could be made per second, to make sure that they could stand up to the vigorous standards of the pro-gamers that had been consulted during the developmental phase.

If you think this is hard wearing on those poor peripherals however, take a look at the next page. Logitech provided us with some short videos of its true physical stress testing of the Orion Spark. It stands up to everything that's thrown at it, but I can't help but feel a bit sorry for the little guy.

Moving through to the “dark room,” we were shown how Logitech develops its backlighting, which is as advanced as anything we've seen from competitors like Corsair's K70 which impressed me a few weeks back.

While I can't speak for Corsair's manufacturing methods, Logitech used its own in-house imaging sensors to detect what kind of light patterns the human eye can pick up, tailoring the LED placement to appeal as much as possible to the user. It also used custom lenses within the Romer G switch itself to guarantee that the entire switch is illuminated, even on larger ones with more expanded clear sections.

For more on what Logitech is doing with its lighting and the firmware driving it, skip forward to the Software page.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

Imagine if you’re one of those lucky people that got 2 of something from the Vending Machine – you’d be extremely happy if that happened here…. 🙂

They don’t do tests for middle mouse click? I hate Logitech since they started using tact switches for middle button and mechanical wheel encoders. Both break fast because I use wheel constantly with 3dsmax! Why not optical wheel sensors and standard switch for MMB? They charge a lot for crap… Better of with another brand mouse.