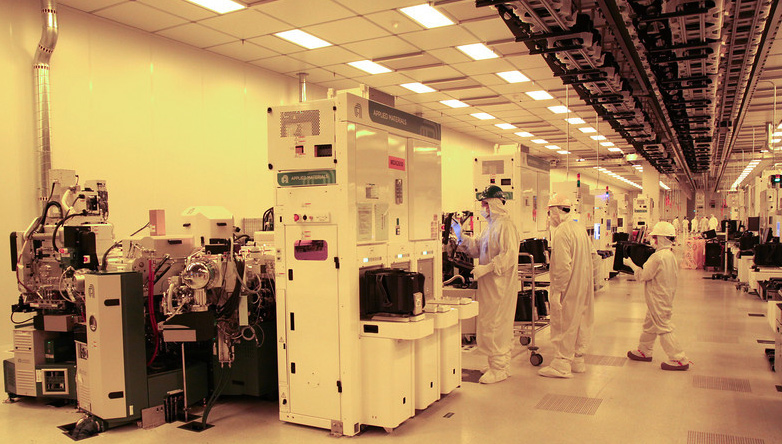

GlobalFoundries, one of the world’s top contract makers of semiconductors, said this week it will upgrade one of its 200mm semiconductor production facilities in Singapore. The move will help the company to expand production capacities and increase output of chips made using advanced fabrication technologies.

Although GlobalFoundries is one of the leading contract makers of semiconductors who can offer process technologies and manufacturing volumes not available from many of its rivals, it still has a number of outdated fabs that process 200mm wafers using rather obsolete fabrication technologies. Apparently, even makers of simple chips now want to produce them more cost efficiently using thinner manufacturing processes at more advanced factories.

Back in 2013 GlobalFoundries acquired 300mm semiconductor manufacturing equipment from ProMOS technologies. This year the equipment will be installed into one of the company’s fabs in Singapore, said KC Ang, corporate senior vice president and Singapore operations general manager at GlobalFoundries, reports DigiTimes. When upgraded, the fab will produce chips using 40nm process technology. At present the fab 6 makes chips using 110nm – 180nm manufacturing processes.

The fab will produce new generations of LCD drivers, power management ICs and fingerprint recognition ICs.

GlobalFoundries expects capital expenditure of $1.0 billion in 2014 and 2015, the executive said.

Discuss on our Facebook page, HERE.

KitGuru Says: Upgrading 200mm and 300mm facilities in Singapore could be GlobalFoundries' way to significantly boost its leading-edge manufacturing capacities. At present the company is not always able to compete for certain orders simply because its arch-rival TSMC can produce significantly more chips using advanced process technologies.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards