Toshiba Corp. and SanDisk Corp. this week said that they have finished development of vertically-stacked 3D NAND memory devices. The BiCS [bit cost scalable] NAND flash memory from the two companies will be mass-produced in 2016 and will enable new solid-state storage devices with enhanced reliability and performance.

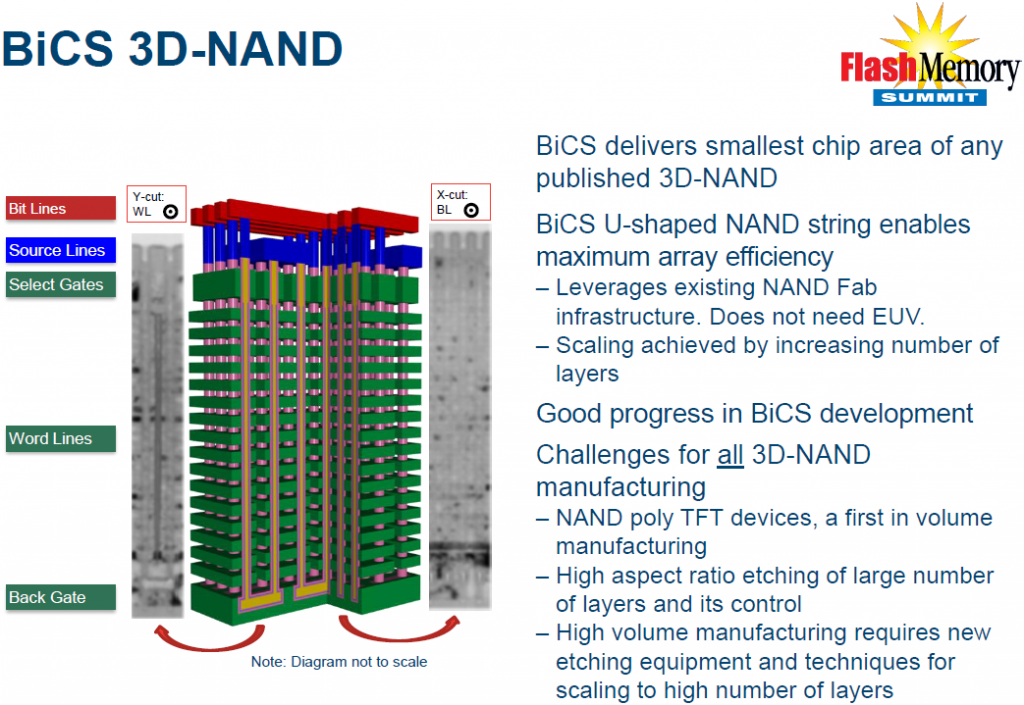

Toshiba’s three-dimensional BiCS NAND flash structure stacks 48 layers of word lines in a 2-bit-per-cell 128Gb (16GB) device. Instead of shrinking size of each cell by making it using thinner process technology, three-dimensional structures increase the amount of memory layers per device. As a result, 3D NAND allows larger areal bit densities without requiring smaller individual cells (hence, no need for leading-edge fabrication processes). The general benefits of 3D NAND flash are well-known by the industry: lower per bit costs (once yields reach commercially viable levels), higher reliability and performance.

Architectural peculiarities of Toshiba’s/SanDisk’s BiCS 3D NAND, such as U-shaped NAND string, enable maximum array efficiency. The latter means that actual BiCS 3D NAND memory chips will always be smaller and cheaper to produce than competing 3D NAND flash memory devices from other manufacturers.

The new BiCS 3D NAND flash memory enhances the reliability of write/erase endurance and boosts write speed compared to planar NAND flash. As a result, applications like solid-state drives powered by 3D NAND will be considerably more reliable than SSDs based on planar NAND made using ultra-thin process technologies.

“We are very pleased to announce our second generation 3D NAND (the first generation 3D NAND by Toshiba/SanDisk was primarily intended for internal testing and development operations – KitGuru), which is a 48 layer architecture developed with our partner Toshiba,” said Dr. Siva Sivaram, executive vice president, memory technology at SanDisk. “We utilized our first generation 3D NAND technology as a learning vehicle, enabling us to develop our commercial second generation 3D NAND, which we believe will deliver compelling storage solutions for our customers.”

Toshiba and SanDisk will start production of BiCS 3D NAND memory in the first half of 2016 in the new Fab 2, which is located in Yokkaichi, Mie prefecture, Japan, once it is completed. The new type of memory will be used across a broad range of solutions, from removable products to enterprise SSDs.

Samsung Electronics has been producing its 3D V-NAND memory in high volume for about 1.5 years now. The company offers a wide range of products based on the 3D V-NAND. Recently Apple started to use Samsung’s 3D V-NAND based SSDs inside new MacBook Air and MacBook Pro laptops.

Discuss on our Facebook page, HERE.

KitGuru Says: While Toshiba and SanDisk are somewhat late to the 3D NAND party, they have a number of architectural advantages in BiCS 3D NAND, which will likely translate into actual benefits of their commercial products. As a result, there will be another round of clashes between SSD makers in 2016, which is good for the consumer.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

A little is late is an understatement to say least, this applies to Intel/Micron as well.

➢➢➢➢86$ PER H0UR@ah4:

Going Here you

Can Find Out,

►►► ::>>https://WorkOnlineLabs.com/get/position…

████████████████████████████