In a bid to ensure steady supply of its latest system-on-chips for its new iPhone smartphones, Apple decided to source the SoCs from two contract makers of semiconductors: Samsung Foundry and Taiwan Semiconductor Manufacturing Co.

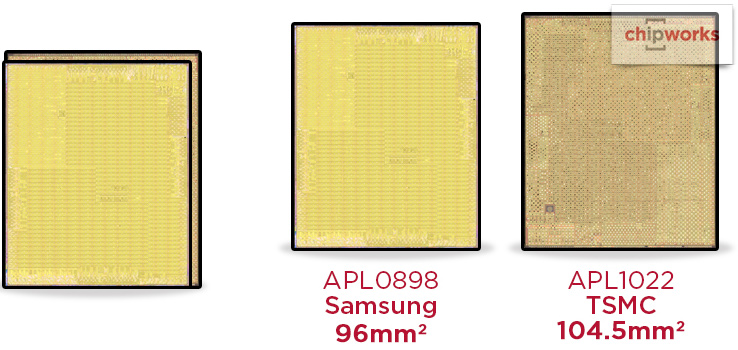

Apple’s new iPhone 6S and iPhone 6S Plus smartphones use A9 processors made by Samsung using 14nm FinFET fabrication process (APL0898) as well as TSMC using its 16nm FinFET manufacturing technology (APL1022), according to Chipworks. The Samsung-made system-on-chip is slightly smaller it has die size of around 96mm2. By contrast, the A9 application processor made by TSMC has die size of around 94.5mm2.

Apple’s new smartphones are expected to be the most popular iPhones ever. The company may sell around 90 million new handsets by the end of the year, which means that it needs 90 million SoCs. Volume requirement is the primary reason why Apple decided to ink supply agreements with two foundries. Sourcing chips from different manufacturers means that Apple will have no problems with supply and will also be able to negotiate the lowest prices.

It is extremely hard to build identical chips using different process technology. It remains to be seen which SoC consumes less power and emits less heat.

Apple did not comment on the news-story.

Discuss on our Facebook page, HERE.

KitGuru Says: It will be very interesting to find out whether Apple also uses GlobalFoundries to produce chips using Samsung’s 14nm LPE [low-power early] fabrication process…

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards