As part of its preparation for the introduction of tough new EU safety requirements for power supplies in 2019, FSP invited KitGuru along to its main office in Taiwan just ahead of Computex 2018. We were given a tour of the safety lab process by the engineer who runs it, Mike Lin, before getting hands on with the first FSP power supply to satisfy the new requirements.

With multiple, large-scale factories dotted across mainland China, FSP claims to produce over 50 million power supplies a year. That figure seems incredible, until you take into account its 3rd party manufacturing of PSUs for other brands and power products for other industries – including power units for televisions and external power bricks for laptops.

From Mike's point of view, the most important aspect of IEC 62368 is that if a unit were to catch fire, the flames must be contained within the power supply and cannot be allowed to escape. Work on the new European standard started ages ago, but you have to wonder if something like IEC 62368 could have helped to prevent the Grenfell Fire tragedy, which was caused by a Hotpoint fridge.

We were shown 13 distinct tests that FSP units must pass. Mike Stressed that his was the product safety department and – in addition to his lab and testing – that R&D had their own facilities (for units that have yet to come to production) and the manufacturing plants themselves also have the ability to pull products out of the line for spot checks. Every PSU will undergo a baseline test to ensure it functions within specified parameters and up to 10% will be pulled for more in-depth testing – which is all part of the certification process required by bodies like TUV and UL.

These are the stages we were shown:

1) Working Voltage Check

Comparing primary (AC mains) to secondary stage (DC internal). The bigger the gap in voltages, the further the physical separation between each section needs to be, in order for the unit to be declared safe.

2) Touch Current Check

Specifically, they are looking for leakage. The main component here is the transformer. You also have a white cap which is designed to reduce noise on the line. It's important that the electricity stays where it's supposed to. Lower quality components can cause a unit to fail this test, but as you increase component quality, you also increase the cost of the PSU. Production specialists need to understand where the ‘balance point' exists and to stay on the safety side of the line.

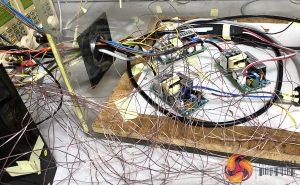

3) Temperature Sensing

Special glue is used to attach sensors to every part of each PCB – measuring temperatures everywhere. The glue is designed to have zero impact on the results. The resulting ‘web' is quite possibly the maddest thing we have ever seen.

4) Environmental Testing

This stage uses an ambient chamber which can deliver a steady 50 degree environment with no airflow.

5) Impact Testing

Definitely the most fun part of the day. Any part of an FSP product that can be touched by a customer, will have been tested by Mike and his assistant Lucifer (we kid you not!). This includes a sturdy ball being dropped from a fixed distance onto the prescribed impact points to show how well a product can withstand being hit hard.

6) No Fingers – No Tools

FSP must ensure that a customer’s finger cannot enter the ‘live’ parts of an AV component, and they do a similar test for ‘small screwdrivers’ with regular PSUs. If contact is possible, then that part must be isolated.

7) Stress Testing

Quite self explanatory this one – power supplies are tested to make sure that all of the components are OK to be stressed past their certified levels.

8) MTBF Calculation

With enough testing, you can calculate the MTBF (mean/average time between failures) for the final supply. Mike's guys are looking for 100,000 hours (around 11 years), but R&D will also force-test selected units to see how they might react to running for 200,000 or even 500,000 hours.

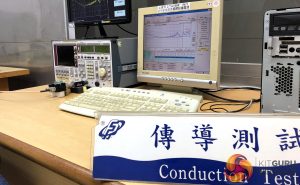

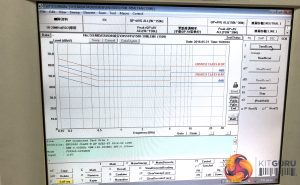

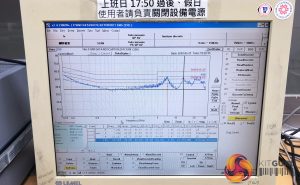

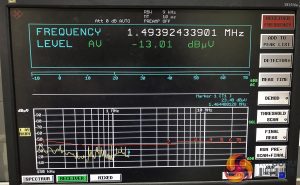

9) Electro Magnetic Interference Testing

This happens in 2 parts. First is conduction testing – to make sure that energy is going through the wire and not exiting sideways. The second is the radiation test. Once the door to the radiation chamber is shut, the giant antenna can pick up signals from 3 metres away. In both cases, the test equipment is looking for less than a 6dB variance.

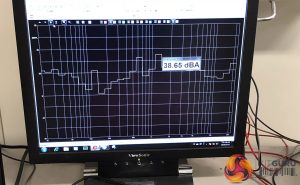

10) Echo Chamber

It's important that power supplies are seen and not heard. We got a slightly wobbly feeling inside the huge anechoic chamber which makes you realise how much of a human's balance is dictated by the way our ears/brain constantly process reflected sound waves. Once the chamber door is shut, the noise in the room drops below 8 dBA.

The unit being tested when we arrived was from the FSP ‘Twin' series, which pairs two PSUs together for redundancy. With two fans instead of one, this is arguably one of the louder set-ups possible. The measurement of 38 dBA is taken by a sensitive microphone positioned 1 metre away – and set at 30 degrees above the unit. Putting the PSU in a case would deaden a lot of that noise and putting the completed system under a desk would render it almost inaudible. Not as quiet as a fanless design, but pretty silent for a regular user. These shots show the test set up, the very thick door to the chamber and the output from dual PSUs.

11) Halt

This is where PSUs are sent to die. This test chamber includes extreme vibration and heat testing. Around 120 degrees should be enough to kill most PSUs (and most people). The same can probably be said for 2 hours of extreme vibration. The ‘Halt' test is designed to stop a PSU in its tracks – so the engineers know what the extreme limits are for the unit's survival.

12) Thermal Shock Test

The FSP engineers working in this section look like normal people, but they definitely have the coolest/most evil kit. I'm told that going from -25C to +80C in 3 minutes is close to the limit for most PSUs. With a smile, I'm informed that -40 degrees to +100 Celsius will ‘do it' for most power supplies.

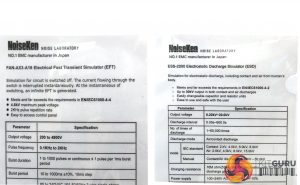

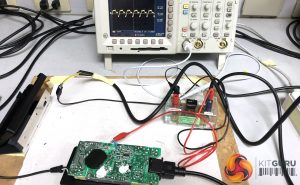

13) Surge Test

Lightning may not strike twice that often in the real world, but this test rig can zap up to 15,000 volts through a product whenever it's needed. The question being asked is ‘can a PSU pass EMS testing – before being killed?'. The second part of the surge test is EFT which varies the input AC voltage by +/-90 volts.

We were then taken to a presentation room and given hands on time with the first FSP power supply to pass not only the existing TUV/UL tests that we had been shown, but also the IEC 62368 safety check.

In the UK, a fire door will be required to protect people for half an hour (for example) before ‘burning through'. Asking how long the unit had to be able to contain an ‘internal fire', we expected a similar answer.

“No. It can't burn through. At all. That is the new standard. In the unlikely event that there was a fire, it must stay inside the unit, flames cannot be allowed to escape”, we were told by Joey, one of the Senior Managers (on the right). The ‘wall shot' shows just how many industries FSP plays a role in.

KitGuru says: It was interesting to see the variety of tests that modern power supplies have to prove that they can endure – and the introduction of the new IEC 6238 standard will make things even safer. We asked about price and when they would be introduced. FSP indicated that pricing wouldn't change by any noticeable amount and that the new, even safer products would be phased in over the coming year. A big thank you to Sean Liao for organising the tour and to Joey Cheng for being our guide around the vast FSP building.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

W

W