No, we aren't missing a picture of a fan here, cause there isn't one!

Cooler Master are using what looks to be a four layered dual-sided PCB for this power supply and it comprises two Y Caps, 1 x X Cap, 2 x CM Chokes and 1x MOV. This is a Full bridge design with LLC converter and the secondary side – synchronous rectification with DC-DC converters. We wanted to use this power supply in upcoming system build videos over on the YouTube channel so I didn't take it completely apart this time. The design of this platform is interesting and giant heatsinks cover the PCB, ensuring that heat can be passively transferred away from the components. As we mentioned earlier, the underside of the chassis has heatpipes incorporated into the design with a heatsink covering the whole outer panel.

Cooler Master have replaced the bridge diodes with an active bridge rectifier to help improve power loss and to improve performance. The active bridge rectifier features four high end Infineon MOSFETs with lower RDS, lower power loss and lower temperatures to also help improve efficiency.

The eagle-eyed amongst you may have noticed the Infineon logo on the front of the box – Cooler Master are using Infineon ‘industrial grade' IC chips for the PFC, LLC, CoolMOS MOSFET, OpiMOS MOSFET and the Infineon Quasi-Resonant 800V. Infineon have a very good reputation in the industry, based in Germany and are their largest semiconductor manufacturer.

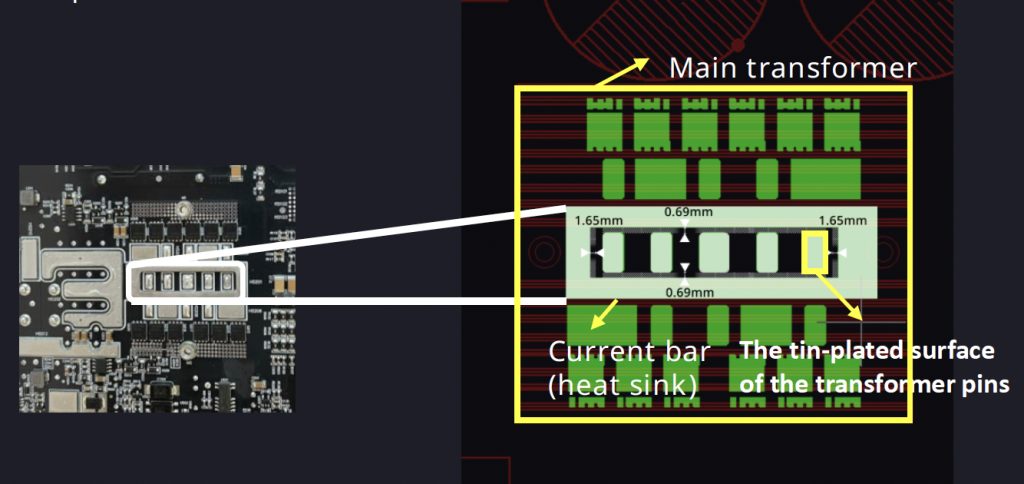

The main transformer takes in heat quickly but to increase the efficiency of heat dissipation SMD heat sinks are added behind the PCB. The distance between the main transformer leads and the heat sinks is reduced to enhance heat dissipation as well.

Cooler Master have adopted flat copper wire winding to increase the copper wire unit area which allows for higher current, reduced impedance, decreased power loss and higher levels of efficiency as well. Cooler Master told us that before they are used, the flat copper wires are hardened with heating and cooling alternatively – this makes the wires stronger. They added that the design of the flat copper wire windings increase the number of layers in the inductor copper core, boosting inductance and reducing friction. In the soldering manufacturing process, it avoids de-wetting issues and the risk of short circuits which subsequently increases reliability.

I did manage to see that the soldering quality throughout is exceptional and at the highest standards – much like the rest of the unit itself. It is certainly a flagship product by any companies standard.

Cooler Master are using a mixture of 105c rated Japanese capacitors in this unit from brands such as Rubycon and Nippon Chemi Con. The two primary caps are from TDK- rated 450V and two at 560uF each for a total of 1120uF. All quality components in both primary and secondary stages.

The unit ships with OPP/ OVP/ OTP / OCP / SCP / UVP and surge and inrush protections.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards