be quiet! are using one of their own 135mm SilentWings 3 fans, with a funnel shaped vent. The funnel shape is said to improve airflow while reducing turbulence. The new 6 pole motor and redesigned bearing lower noise further. This fan, as mentioned already in the review has the slowest start up speed of any fan on the market – 220 rpm.

This fan is rated slightly differently to the one we saw in the 850W unit earlier this year. The 550W fan is labeled ‘BQ SIW3-13525-MF' and the fan inside the 850w unit is labeled ‘BQ SIW3-13525-HF'. The MF model in the 550W unit has a maximum rated rotational speed of 1,200 rpm and operates at 0.4A – the HF model used in the higher capacity units has a maximum rated rotational speed of 1,500 rpm and operates at 0.56A.

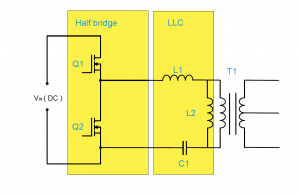

The topology of this particular unit is ‘Half Bridge + LLC + SR + DC/DC'. The topology of the higher capacity units is ‘Full Bridge + LLC + SR + DC/DC'. So what exactly does this mean?

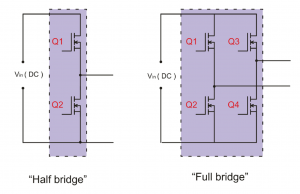

A Full Bridge implementation relates to the number of MOSFETs used in the PWM stage. The MOSFETS are responsible for creating high frequency alternating current – the best efficiency for the main transformation.

A Half Bridge design uses two MOSFETS, a Full Bridge doubles this to four – reducing the load across them all, this is important for higher wattage units. The LLC part of the name relates to the use of two inductors and one capacitor – this smooths out the alternating current – giving very high levels of efficiency, critical to achieve 80 Plus Platinum efficiency.

The Dark Power Pro 11 can use frequency modulation (FM) along with pulse width modulation (PWM) to adjust the power transformation. At around 10-15 percent load, the LLC circuit will modify the frequency to give excellent efficiency levels. Good results can be reached with low frequencies at high loads, and vice versa.

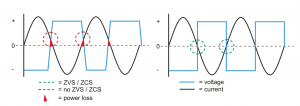

The Dark Power Pro 11 utilises zero voltage switching and zero current switching technology. This essentially captures power lost by other topologies with switching done at the zero line. A traditional topology cannot control the switching point to the same degree so there is some switching loss. With a ZVS/ZCS implementation this ‘lost' power is captured, giving better efficiency.

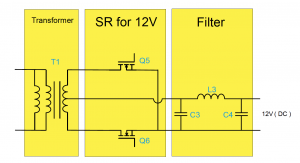

When the alternating current passes the main transformer it gets rectified and switched into 12V DC current. This process is achieved by four MOSFETS (in the lower wattage Dark Power Pro 11 units) and by eight MOSFETS (in the higher wattage units) – subsequently synchronised by using a dedicated IC. This IC (in the Dark Power Pro 11 anyway) is called the CM6901.

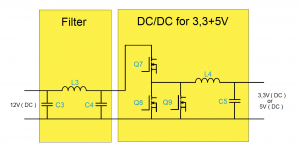

Like many high grade, efficient units we have tested in recent months, the Dark Power Pro 11 utilises DC/DC technology. Instead of generating 3.3V, 5V and 12V from the AC on the primary side, the lower 3.3V and 5V voltages are generated from 12V DC after the primary transformation takes place.

The engineering standards are very high, and soldering quality is very good throughout.

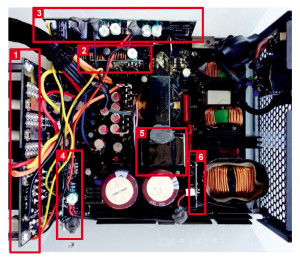

1. CM board (Cable Management)

2. DC/DC board for 3.3 and 5V

3. Protection board

4. LLC control board (with IC)

5. LLC board with the „L“ of LLC

6. Control circuit for PFC MOSFET´s (by IC)

The 550W, 650W and 750W Dark Power Pro 11 power supplies are complimented with 6 daughter cards, highlighted above. be quiet! claim that by using these daughter boards the interior layout is improved, helping enhance air flow. This higher build density means shorter circuit paths.

The Dark Power Pro 11 550W power supply incorporates two 105c rated Japanese capacitors in the primary stage – rated 450V 220uF. This time Rubycon capacitors are used, while we noted Nippon Chemi Con inside the 850W unit earlier this year. We consider both companies to produce some of the best capacitors for this specific market. be quiet! have enhanced the design of the PFC stage by using special high quality plastic capacitors to reduce noise – exceeding the quality of the capacitor in the previous generation model.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards