| General Data | |

| Manufacturer (OEM) | MEIC |

| Primary Side | |

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV, 1x CM02X |

| Inrush Protection | NTC Thermistor & Relay |

| Bridge Rectifier(s) |

2x GBU1006 (600V, 10A @ 100°C)

|

| APFC MOSFETS |

2x Alpha & Omega AOT42S60 (600V, 25A @ 100°C, 0.28Ohm @ 150°C)

|

| APFC Boost Diode |

1x CREE C3D08060A (600V, 8A @ 152°C)

|

| Hold-up Cap(s) |

2x Nippon Chemi-Con (400V, 390uF, 2000h @ 105 °C, KMR)

|

| Main Switchers |

2x Alpha & Omega AOT42S60 (600V, 25A @ 100°C, 0.28Ohm @ 150°C)

|

| APFC Controller |

Champion CM6500UNX & CM03X Green PFC controller

|

| LLC Resonant Controller |

Champion CM6901

|

| Topology |

Primary side: Half-Bridge & LLC Resonant Controller

Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V MOSFETS | 4x Alpha & Omega AOT2142L (40V, 120A @ 100°C, 1.9mOhm) |

| 5V & 3.3V | DC-DC Converters: 8x GV8G16 PWM Controller: 2x NCP1587 |

| Filtering Capacitors | Electrolytics: Chemi-Con (1-5,000 @ 105°C, KZE), Chemi-Con (4-10,000h @ 105°C, KY) Polymers: Chemi-Con |

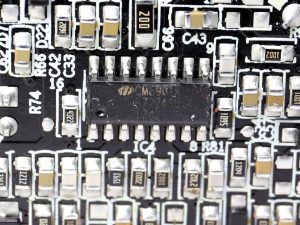

| Supervisor IC | Weltrend WT7527A (OVP, UVP, SCP, OCP, PG) |

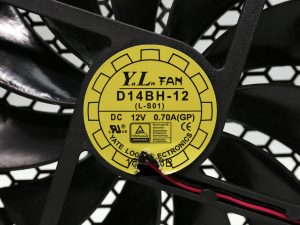

| Fan Model | Yate Loon D14BH-12 (140mm, 12V, 0.70A, 2800 RPM, 140CFM, 48.5 dBA, Double-Ball Bearing) |

| 5VSB Circuit | |

| Rectifier |

1x TPD65R1K2C (650V, 4A @ 25°C, 1.2Ohm)

|

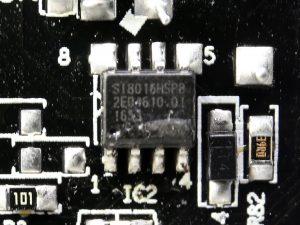

| Standby PWM Controller | SI8016HSP8 |

The original manufacturer of this unit is MEIC, for which we don't know much since so far we mostly know this OEM from its power adapters. The design is modern using an LLC resonant converter in the primary side along with a half-bridge topology.

In the secondary side a synchronous rectification scheme is used for the +12V rail and the minor rails are regulated through a couple of voltage regulation models.

All filtering caps are provided by Chemi-Con, both electrolytic and polymer ones, showing that Gigabyte asked for a very reliable platform. This is also shown by the double ball bearing fan, although Yate Loon is not among the most respectable fan makers nowadays.

Still back in the day the AX1200 used exactly the same fan, with the GP-AP850GM!

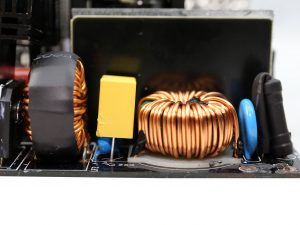

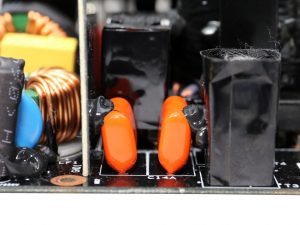

The first part of the transient filter resides on a small PCB and includes one X and two Y caps, along with a CM02X IC, which blocks the X cap's discharge resistors once power is connected. The second part of the EMI filter is on the main PCB and consists of one X and two Y caps, two CM chokes and an MOV (Metal Oxide Varistor).

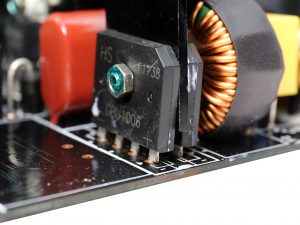

The couple of bridge rectifiers is installed on a leaning heat sink. Combined the pair of GBU1006 rectifiers can handle up to 20 Amps of current.

There is an NTC thermistor for protection against large inrush currents, and a bypass relay supports it. We expect to find this relay in every high-end platform since besides a small efficiency boost it also allows the fast cool down of the thermistor, so inrush currents are always kept under control (as long as the used thermistor is up to the task of course).

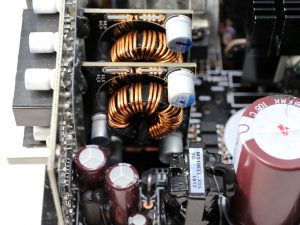

In the APFC converter two Alpha & Omega AOT42S60 FETs are used along with a CREE boost diode. Both bulk caps are provided by Chemi-Con and their combined capacity reaches 780uF, which barely meets the needs of this unit. Apparently MEIC had to use those 390uF caps since the next inline KMR cap has notably larger capacity, at 470uF and there is also the cost difference, since those caps don't come cheap.

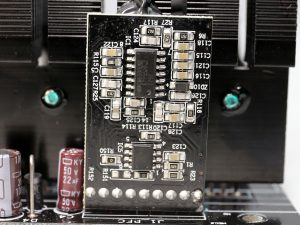

The PFC controller is a Champion CM6500UNX IC, which is supported by a CM03X Green PFC controller that lowers power consumption in standby mode. Both are installed onto a small vertical board.

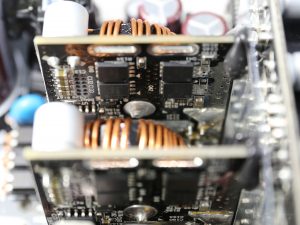

The primary FETs, a pair of Alpha & Omega AOT42S60, are arranged in a half-bridge topology.

The LLC resonant controller is a Champion CM6901. This controller is heavily used in high efficiency PSUs.

The main transformer of the unit. Right next to it is the resonant tank and the capacitive components of the LLC resonant converters, a couple of X caps. There is also a shield between the transient filter and the resonant tank, providing protection against radiated EMI.

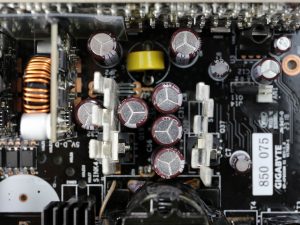

The +12V rail is regulated by four Alpha & Omega AOT2142L FETs. The filtering caps are by Chemi-Con and belong to the KZE and KY lines, which are popular in high-end PSUs.

The minor rails are generated through a couple of voltage regulation modules (VRMs). Each of them uses four GV8G16 FETs and a NCP1587 PWM controller.

The standby PWM controller (SI8016HSP8) is installed on the solder side of the PCB and its primary switching FET, TPD65R1K2C, is close by.

The PSU's protections handles a Weltrend WT7527A IC, located at the back side of the modular board. This IC also has over current protection for up to two +12V rails, besides the minor ones.

At the front side of the modular PCB, which is connected to the main board through a number of bus bars, a number of polymer Chemi-Con caps provides an extra ripple suppression layer.

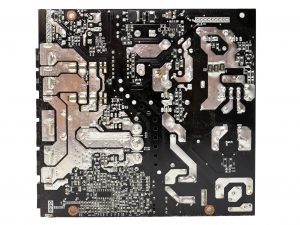

The soldering quality on the main PCB is quite good. We also noticed that in our sample at least the solder most likely contains lead, since it was quite easy to desolder parts. In our opinion lead-free solder although it is supposed to be more environmental friendly, in the end it does more damage because of the increased number of failures in the devices that use it.

Lead-free solder joints crack easier and on top of that, the higher temperatures required by this type of solder can damage sensitive components. Tin whiskers are also a problem.

The cooling fan is provided by Yate Loon (D14BH-12) and it is very strong for a 850W and highly efficient platform like this one. It uses double ball bearings meaning that it won't have a problem operating under tough conditions. The fan profile is not aggressive, so under normal operation the PSU will be silent.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards