MSI’s £210 competitor comes in the form of the MPG X570 Gaming Edge Wi-Fi. Just like ASUS’ offering, this name is annoyingly long! MSI deploys the typical motherboard colour scheme of dark greys and blacks which looks pretty good in my opinion. A massive RGB lighting edge is one of the key features for MSI.

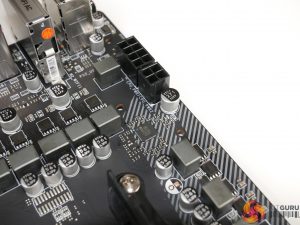

Focusing on the power delivery system, MSI equips this motherboard with an 8+2 phase physical implementation.

MSI is using the superb International Rectifiers IR35201 PWM controller in a 4+2 phase mode.

A total of five IR3598 phase doublers/dual drivers are deployed on the rear PCB. Four of these are used in doubler mode to double the four PWM phases allocated for CPU VCore and drive the eight sets of high- and low-side MOSFETs. The remaining IR3598 is deployed in dual driver mode to drive the two pairs of high- and low-side MOSFETs allocated for the 2-phase SoC VRM.

As such, MSI’s 8 CPU VCore phases are actually a 4×2 design and the SoC is a pure 2-phase design.

Focussing specifically on the 4×2-phase CPU VCore MOSFET solution, MSI is using 4C029N and 4C024N High- and low-side MOSFETs from On Semi. A total of eight of these pairs are deployed, so this VRM solution would be most closely matched to ASRock’s 8-phase X570 Steel Legend.

With that said, the ‘dumb’ On Semi discrete MOSFETs are undeniably basic for a £210 X570 motherboard, they take up more PCB real estate than co-packaged power stage solutions, and there is a high likelihood of higher electrical losses simply by virtue of the high- and low-side MOSFETs being physically detached from one another. Their thermal resistance ratings aren’t great compared to the Vishay DrMOS power stages, either.

The 2-phase SoC VRM is made up of two pairs of discrete MOSFETs. I could not find details about these solutions as the writing is unclear and the model is uncommon. These are driven by the rear mounted IR3598 dual driver.

As was the case with Gigabyte, the SoC VRM is undeniably basic in terms of electrical component quality. However, this is likely to be a non-issue for most X570 users who will be running with a dedicated graphics card.

MSI provides an additional 4-pin power connector to supplement the 8-pin one. This isn’t necessary for a board of this calibre as you’re unlikely to saturate a single 8-pin.

Yet again, we see heatsinks with a design more focussed on aesthetics than cooling efficiency. For the larger, left-side heatsink, there are no fins or real attempts at designing in fins, other than a few ridges in certain locations. The top heatsink is clearly given a little more attention when it comes to surface area, with stacked ridges found on the front and back positions.

Mounting sturdiness is good thanks to the screw fit. The thermal pads applied by MSI looked to be thicker than those found on competing vendors’ solutions and they didn’t seem to be applying as much pressure to the MOSFETs, as judged by the minimal imprints when removing the heatsink.

The larger left-side heatsink weighs a massive 247 grams while the smaller top heatsink is a solid 84 grams. Clearly, MSI is aiming for a brute force approach at dealing with the heat output from its less efficient MOSFET solutions.

That roughly 3:1 split for heatsink mass is pretty much ideal, as the larger left side heatsink is tasked with cooling six CPU power phases while the smaller top heatsink is given two phases to cool, plus the less-demanding SoC VRM.

If MSI’s heatsink design can remove the electrical resistance heat from the MOSFETs, there should be no concerns for reduced performance. That does, however, demand at least a decent amount of case airflow to interact with the metal cooling slabs.

While MSI’s heatsink design isn’t as efficient as it could be, there is a massive slab of metal with a relatively high amount of surface area via a brute force approach. This large heatsink will help to dampen any sudden changes in MOSFET temperatures when short, heavy loads are applied. But for sustained heavy loading, there still needs to be sufficient surface area for the heat to be dumped away from the metal block.

Overall, I’d say MSI has the best heatsink design of all four boards on test today, simply by brute force. Sometimes, there doesn’t need to be elegance to the approach – a big chunk of metal can potentially be a solid solution.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards