SanDisk Corp. and Toshiba Corp. are on-track to start volume shipments of products based on their BiCS [bit cost scalable] 3D NAND flash memory in 2016. Recently the two companies began to purchase equipment needed to manufacture vertically stacked NAND chips and will initiate pilot production later in 2015. Moreover, it seems that SanDisk plans rather rapid ramp of BiCS 3D NAND.

New fab for new memory

“We have begun our equipment purchases to support the commencement of pilot production of our 48-layer [NAND] architecture in the second half of 2015,” said Judy Bruner, chief financial officer, during the company’s earnings conference call with investors and financial analysts. “We are on track to begin using the pilot line output for product samples in 2015, and we continue to expect 3D NAND product sales to begin in 2016.”

Production of BiCS 3D NAND will start in a new fab, which construction has been completed recently. The two companies have never revealed actual production capacity of the new semiconductor fabrication plant, but indicated multiple times that its clean room space would be built in phases to align the clean room investment “with the timing of conversion of 2D NAND capacity to 3D NAND”. Actual production levels in the new fab are expected to “reflect market trends”. To build the the new semiconductor fabrication plant, SanDisk and Toshiba demolished their outdated fab 2 last year. Eventually, some of existing planar NAND capacities at fab 5 phase 1 and phase 2 will be converted to 3D NAND.

Smallest 3D NAND

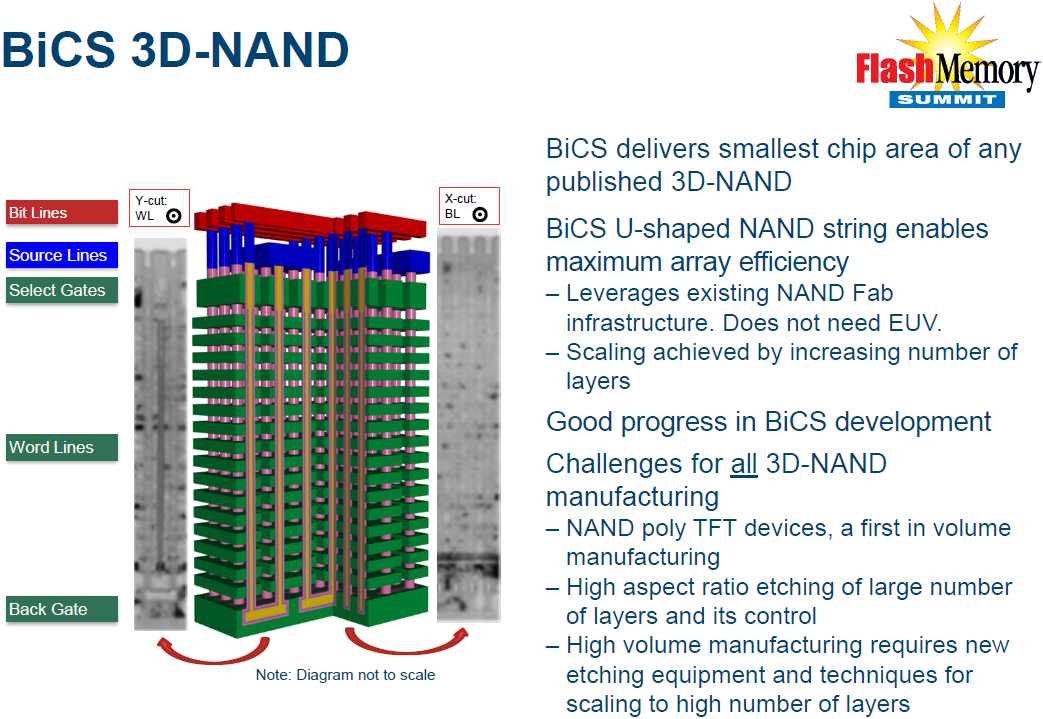

The three-dimensional BiCS NAND flash structure stacks 48 layers of word lines in a 2-bit-per-cell 128Gb (16GB) device. Architectural peculiarities of BiCS 3D NAND, such as U-shaped NAND string, enable superior array efficiency compared to 3D NAND architectures from other companies. Market observers expect BiCS 3D NAND memory chips to be smaller and cheaper to make than competing 3D NAND flash memory devices. The new BiCS 3D NAND flash memory promises to increase write/erase endurance and reliability as well as to boost write speed compared to planar NAND flash.

“The 48-layer technology provides an excellent combination of increased density, higher performance and lower power compared to 2D NAND,” said Ms. Bruner.

Rapid ramp

Initially, SanDisk will use its BiCS 3D NAND flash to produce various memory cards, but shortly after such memory will be used for client solid-state drives and embedded applications. The company will use its stacked NAND memory for enterprise-class applications later this decade.

“We plan to implement our 3D NAND first in high-capacity removable products, then client SSDs and embedded solutions, followed by enterprise SSD solutions, which have longer design and qualification periods,” said the CFO of SanDisk.

According to estimates by SanDisk, 3D NAND will account from 15 to 20 per cent of NAND flash memory produced in the industry in late 2016. SanDisk expects around 15 per cent of its non-volatile memory to be 3D by the end of 2016, which indicates a very rapid ramp of the new production plant.

“Our expectation is that the industry will likely exit 2016 in the range of 15 to 20 per cent of wafer capacity on 3D NAND,” said Ms. Bruner. “Our expectation is that we will likely be around the low end of that range.”

Discuss on our Facebook page, HERE.

KitGuru Says: Although Toshiba and SanDisk will start volume production of vertically-stacked 3D NAND memory considerably later than Samsung Electronics, it looks like the two companies want to rather rapidly ramp up production of such memory, which will improve performance of their products.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards