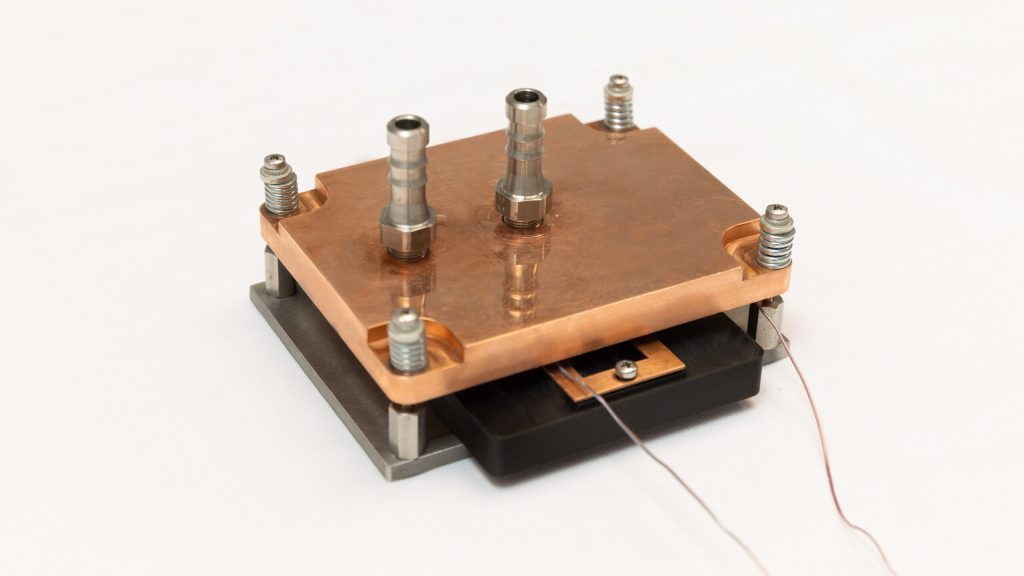

CoolIT Systems has unveiled an interesting liquid cooling coldplate capable of dissipating a remarkable 4000W of heat. This achievement surpasses existing industry standards for single-phase direct liquid cooling (DLC) products twofold.

As the name implies, direct liquid cooling involves bringing a liquid coolant into direct contact with heat-generating components, such as CPUs or GPUs. The “single-phase” designation indicates that the coolant remains in a liquid state during the whole loop (e.g., AIOs and custom loops), unlike two-phase systems, where it transitions between liquid and vapour during the loop (air cooler heatpipes).

CoolIT's new cold plate efficiently transfers heat from the processor to the coolant, which the company specifies as water or a water-glycol mixture. In standardised testing, with a flow rate of six liters per minute (LPM), the cold plates demonstrated a 97% heat removal efficiency from a 4,000 W thermal source. The company also reported the coldplate has a thermal resistance of less than 0.009 Celsius/Watt (lower thermal resistance value means more efficient heat transfer) and a full-flow loop pressure drop of 8 PSI (reduced pressure drop minimises the workload on the coolant pump in a closed-loop system).

As global competition among technology giants intensifies, chipmakers are pushing the boundaries of performance, often at the cost of increased power consumption. Amplified by the growing density of server racks, this trend has driven the adoption of liquid cooling technologies in data centres. While immersion cooling offers a viable long-term solution, its infrastructure requirements and limitations on vertical rack stacking make D2C solutions a more readily deployable option for the foreseeable future.

Discuss on our Facebook page, HERE.

KitGuru says: Do you think we'll ever need this level of cooling capability in our home setups?

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards