As much as we're excited by the ventures of Space X and Amazon in making travel into space and the transport of materials into orbit that much cheaper with their re-usable systems, they're not the only ones looking to revolutionise space travel. British company Reaction Engines has designed a new engine which it claims can operate as a jet engine and a rocket, interchangeably.

A single stage to orbit vehicle is the holy grail of re-usable space travel. Ditching the necessity to carry huge additional stages which are jettisoned (or perhaps landed safely in the case of the Falcon 9) would save a lot of money, resources and build time, but it's yet to be done successfully. Although the Space Shuttle offered some measure of a re-usable, multi-stage vehicle, it wasn't anything quite like what Reaction Engines is proposing.

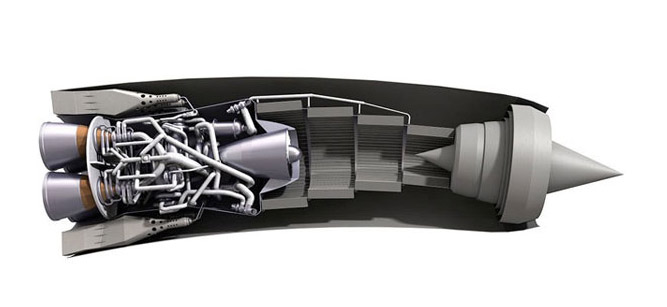

Its design is able to operate as a traditional rocket engine and as a jet-turbine, letting it fly through the atmosphere, using the oxygen in the air as its oxidiser (instead of carrying hundreds of tonnes of liquid O2), only switching over to rocket mode and using onboard stores of O2 when the atmosphere thinned out.

It achieves this by supercooling air as it comes into the turbine, reducing its temperature to near-liquid (but not quite) levels, before funnelling into the turbine.

Although not as useful for sending heavy payloads into orbit, the conceptual space-craft that Reaction Engines has designed around its specialised engines would be able to carry reasonable payloads into orbit and return to Earth far more efficiently. They claim that it could cut the cost of travelling to low-Earth Orbit by a factor of 10.

In comparison, Space X's reusable first stage rocket would cut costs in half or perhaps a little further.

Reaction engines has further tests planned for its engine, but says that it will soon begin final designs for its concept space ship.

Discuss on our Facebook page, HERE.

KitGuru Says: This is a pretty interesting piece of technology as it shows real versatility. Being able to take advantage of the much more efficient travel of traditional aircraft with fixed wings would make even more savings in terms of fuel and materials over traditional space travel.

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

KitGuru KitGuru.net – Tech News | Hardware News | Hardware Reviews | IOS | Mobile | Gaming | Graphics Cards

SpaceX is gunning for far more than a halving of the cost…they already offer commercial payload delivery for $78m dollars, or about £50m, and Musk has stated many times he intended to eventually reduce it to $500,000 per a space launch, and only a freight fee of a few thousand dollars per a tonne.

SpaceX is gunning for far more than a halving of the cost…they already offer commercial payload delivery for $78m dollars, or about £50m, and Musk has stated many times he intended to eventually reduce it to $500,000 per a space launch, and only a freight fee of a few thousand dollars per a tonne.

I thought it would be easier the other way around- vaporize liquid o2 with the engine consuming gaseous o2 rather than liquefying air. You could have an electric operated pump that can achieve that.

In any case, the bigger problem, IMO is that liquid o2 is not the same as liquid ‘air’ and same goes for o2 vs air. In the latter case, it may only be a matter of preparing an engine that can operate under various ratios of air/fuel. Even so, reaction between H2/O2/N2 must ALSO be taken into account at those temperatures.

Wow ! Not as simple as it looks.

I thought it would be easier the other way around- vaporize liquid o2 with the engine consuming gaseous o2 rather than liquefying air. You could have an electric operated pump that can achieve that.

In any case, the bigger problem, IMO is that liquid o2 is not the same as liquid ‘air’ and same goes for o2 vs air. In the latter case, it may only be a matter of preparing an engine that can operate under various ratios of air/fuel. Even so, reaction between H2/O2/N2 must ALSO be taken into account at those temperatures.

Wow ! Not as simple as it looks.

Write again in 20 years when the engine is actually being used for flight to orbit. Easy to design a rocket engine, much more difficult to make it actually work.

Write again in 20 years when the engine is actually being used for flight to orbit. Easy to design a rocket engine, much more difficult to make it actually work.

using super cooled o2 would be more efficient to burn if only because it would be denser, better fuel air reaction so the most energy generated from the burn. can’t speak to the efficiency of super cooling the o2 on the fly as the article suggested though.

using super cooled o2 would be more efficient to burn if only because it would be denser, better fuel air reaction so the most energy generated from the burn. can’t speak to the efficiency of super cooling the o2 on the fly as the article suggested though.

“Easy to design a rocket engine” – any highschool dropout can get a Master’s Degree in Aeronautical and Astronautical Engineering! It’s not like it’s rocket science or anything!

“Easy to design a rocket engine” – any highschool dropout can get a Master’s Degree in Aeronautical and Astronautical Engineering! It’s not like it’s rocket science or anything!

But then…

You have to carry tonnes of liquid oxygen (like the article said).

The cooling of air is “free” since it uses the liquid fuel already at near 0. This means, while in atmosphere, the engine needs to carry a fraction of the propellant for the same delta V, making it more efficient.

The air is cooled to make the jet engine work at mach 5+, if the air enters the combustion chaimber at 1000 degrees (this happens under the shockwave compression at these speeds) then it has “nowhere to go” when burnt i.e. there will be little expansion since the air is already close to max heat.

The greater the temperature difference between air in and air out, the greater volume increase (and hence thrust) can be gained.

But then…

You have to carry tonnes of liquid oxygen (like the article said).

The cooling of air is “free” since it uses the liquid fuel already at near 0. This means, while in atmosphere, the engine needs to carry a fraction of the propellant for the same delta V, making it more efficient.

The air is cooled to make the jet engine work at mach 5+, if the air enters the combustion chaimber at 1000 degrees (this happens under the shockwave compression at these speeds) then it has “nowhere to go” when burnt i.e. there will be little expansion since the air is already close to max heat.

The greater the temperature difference between air in and air out, the greater volume increase (and hence thrust) can be gained.

It’s true, I’ve designed multiple rocket engines from a mixture of bubblegum, paper clips and bone china. None of the buggers got off the launch pad made out of cardboard though, didn’t even move an inch.

It’s true, I’ve designed multiple rocket engines from a mixture of bubblegum, paper clips and bone china. None of the buggers got off the launch pad made out of cardboard though, didn’t even move an inch.

It’s not too hard. 🙂

http://www.instructables.com/id/Homemade-rocket-with-rocket-fuel-and-engine/?ALLSTEPS

The rocket does work, it has already been tested.

The craft to put it in, on the other hand, is another matter!